- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

No. | Item | Quantity | Remarks |

1 | Indicator | 1 set | Nantong Great Profit |

2 | Numerical control system | 1 set | Estun E21S |

3 | Hydraulic system | 1 set | Uoshen Hydraulic |

4 | Seal | 1 set | Taiwan Dingzing |

5 | Button | 1 set | China Tengen |

6 | Oil pump | 1 set | Vibo Hydraulics |

7 | Main electrical component | 1 set | China Tengen |

Front Gauge and Back Gauge

● Front gauge: More convenient to use the front gauge to shear thin steel plates.

● Back gauge: Adjustment is convenient and reliable.

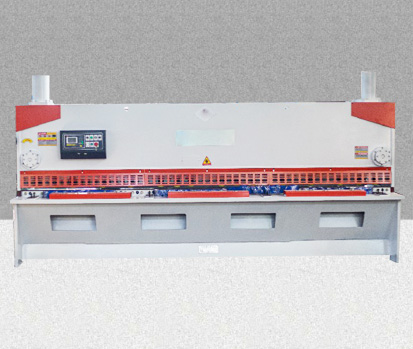

V. Product Shape and Structure

● Analysis method, computer aided optimization design.

● Integral steel plate welding structure has good strength, rigidity and vibration resistance.

● Using German technology to relieve internal stress.

● Sand blasting method for the machine bed to remove rust, and sprays anti-rust paint.

VI. Performance Characteristics

● An auxiliary cutter base provided on the working workbench, which is convenient for micro-adjustment of the cutter blade.

● A feeding ball on the working workbench, which is easy to operate.

● A stepless adjustment mechanism to meet the shearing needs of different plate thicknesses and materials.

● Rectangular lower blade that can be cut with four cutting edges, which prolongs the service life of the blade.

● Adjusting the shearing stroke can not only improve the processing efficiency, but also realize the segmented shearing function.

● Automatic counting of cutting times reduces tedious counting work.

VII. Hydraulic System

placed on the upper part of the machine and consists of electric motors, pumps, valve blocks, pressure displays, pipelines, etc

● Motor

a fully enclosed, self-fan-cooled, three-phase asynchronous motor.

● Oil pump

Long service life and low noise.

● Valve block

TTwo-way cartridge valv

● Fuel tank

The fuel tank is a steel plate welded structure, which is pickled and rust-proof when installed.

● Pipeline

Flange connection as far as possible to prevent pipeline leakage.

● Material pressing mechanism

After several pressure oil cylinders installed on the support plate in front of the frame are fed with oil, the pressure head overcomes the tension of the tension spring and presses down to tighten the plate material. After the shearing is completed, it is reset with the help of the pulling force of the tension spring. The magnitude of the pressing force increases with the increase of the thickness of the sheared plate.

● Pressure Display

Anti-seismic pressure gauge filled with silicone oil.

● Equipped with an oil filtration system to ensure stable and reliable machine operation.

● Emergency stop and other actions during work.

● The sealing ring from Taiwan Dingzing Company has good sealing performance, reliable work and long life.

● Stablity and high precision.

VIII. Electrical Control System

● Electrical components and materials conform to international standards, safe, reliable and have a long lifespan.

No. | Name | Value | Unit | |

1 | Maximum shear thickness | 4 | mm | |

2 | Maximum shear plate width | 3200 | mm | |

3 | Shear plate strength | 450 | N/mm2 | |

4 | Shear angle | 1º30' | ||

5 | Maximum distance of backgauge | 500 | mm | |

6 | Blade length | 3300 | mm | |

7 | Main workbench height | 800 | ||

8 | Main motor | Model | 4 | KW |

Power | 7.5 | r/min | ||

Rotational speed | 1400 | mm | ||

9 | Back gauge motor | Model | 6 | |

Power | 0.37 | KW | ||

Rotational speed | 900 | r/min | ||

10 | Gear pump | Model | 20 | |

Flow rate | 20 | ml/r | ||

Pressure | 31.5 | Mpa | ||