- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

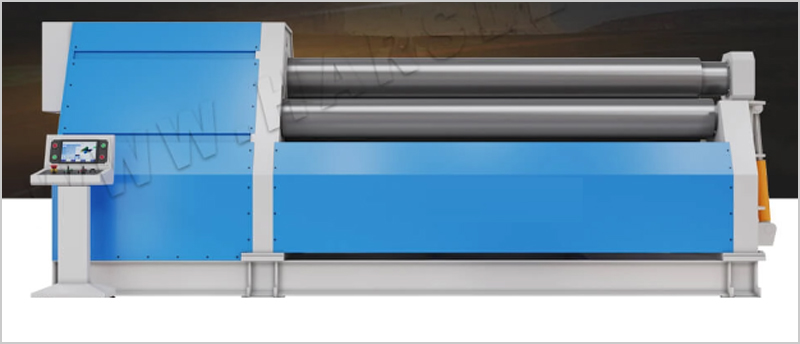

Steel metal rolling machine is used for forming and shaping metal plates into curves and cylindrical shapes.

The machine consists of large rollers that press and bend the plate as it passes through. The finished product is a uniform, seamless shape that is used in various applications such as construction, shipbuilding, and manufacturing.

Sheet metal rolling machines can be manual or automated, with different configurations and features depending on the specific use and material type. We are specializing in the design, manufacturing and sale of plate bending rolls, and offer the widest range of plate bending machines available on the international market.

Our bending rolls, suitable for bending plates in a variety of thicknesses, are technologically advanced products capable of bending varyingly thin or thick plates offering maximum precision, high productivity and long term reliability.

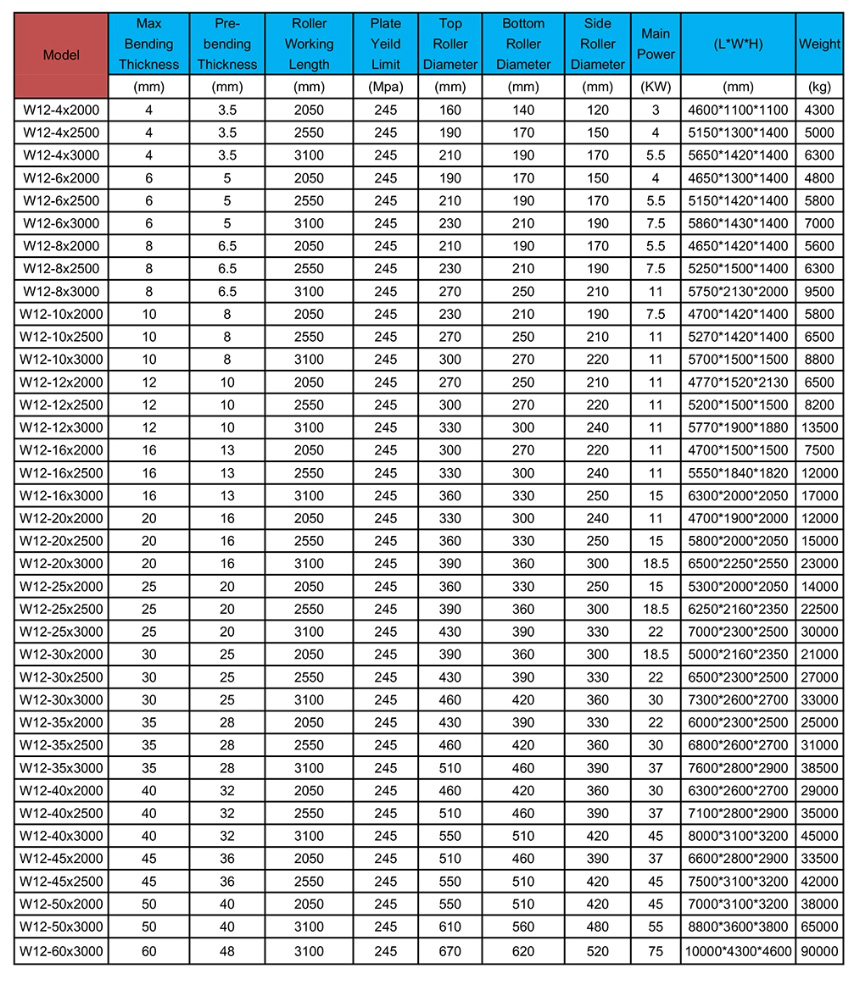

Four-Roller Hydraulic Sheet Metal Rolling Machine

No. | Main Machine Part | Technical Requirement | ||

1 | Top Roller Device | Material | 45# | |

Techniques | Middle carbon steel , quenching and tempering treatment at HB190~220 | |||

finish turning then medium frequency quenching of surface at HRC48~52 | ||||

2 | Bottom Roller Device | Material | 45# | |

Techniques | Middle carbon steel , quenching and tempering treatment at HB190~220 | |||

finish turning then medium frequency quenching of surface at HRC48~52 | ||||

3 | Side Roller Device | Material | 45# | |

Techniques | Middle carbon steel , quenching and tempering treatment at HB190~220 | |||

finish turning then medium frequency quenching of surface at HRC48~52 | ||||

4 | Side Frame and Chassis | Material | Q235 steel | |

Techniques | Fixed and tipping side frame and chassis are welding pieces of steel plate. | |||

1.Welding 2.Anneal and vibration 3.The stress shall be eliminated | ||||

5 | Drive Device | Motor | SIEMENS(380V/50HZ) | |

Reducer | From china famous supplier | |||

6 | Hydraulic System | Fluid pressure pump | Type | Gear pump |

Manufacturers | HCHC China | |||

Hydraulic valve | Manufacturers | YUKEN Japan | ||

Oil cylinder | Sealing element | UN type | ||

Manufacturer | DZ TAIWAN | |||

7 | Tipping Device | Function | Get bended work piece | |

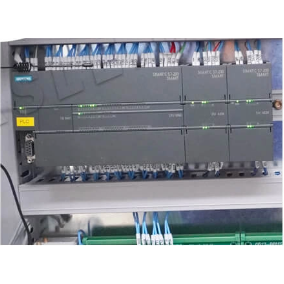

8 | Control System | Quality standard | CE | |

Low voltage apparatus | SIEMENS GERMAN | |||

PLC | OMRON JAPAN | |||

Touch screen | WEINVIEW Taiwan 10 inch | |||

Control program | Nantong Annan | |||

9 | Bearing | Double-row Self-aligning Roller Bearing | HRB/ZWZ | |

10 | Encoder | From china famous supplier | ||

We can provide:

|  |  |

| CNC Rolling Programming | Three/Four/Five Roller Machine Structure | Hydraulic Working Method Pre-bending Available |