- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

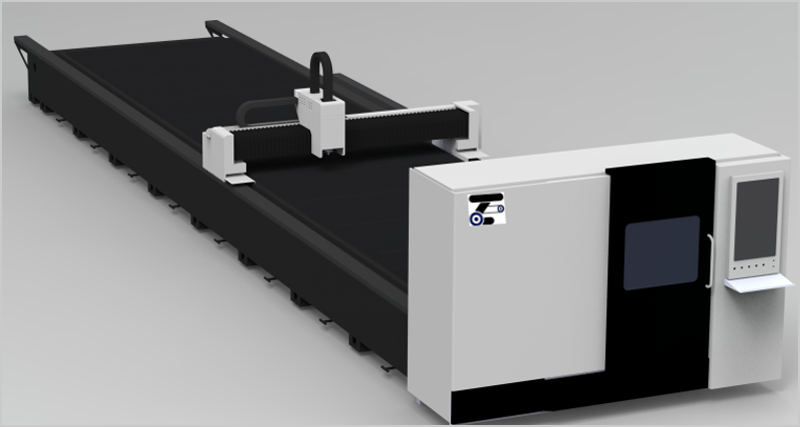

This fiber laser cutting machine has the advantages of intelligence, high efficiency and high stability: It is made of the mature mechanical technology that has reached the advanced level in China and the world, and this series is the first choice for the sheet metal fabrication industry. The machine bed is of a honeycomb carbon structure, which is welded with steel plates and thick-walled square pipes. After aging annealing to relieve stress and surface shot blasting, it has extremely high strength and stability. The crossbeam is of lightweight aviation cast aluminum. Equipped with high-performance servo drive and helical tooth drive with high precision, the running speed is extremely fast and the precision is extremely high.

Confiruations

S/N | Name | Model | Quantity | Remarks | |

1 | Cutting machine body and cross member | ZF-3015H | 1 set | Zhongfa | |

2 | Laser | 3000W | 1 unit | Maxphotonics | |

3 | Special Water Chiller for Fiber Laser | 3000W | 1 unit | S&A | |

4 | High Precision Professional Optical Fiber Cutting Head | Fiber optic cutting head | 1 unit | RayTools | |

5 | Control system | Bochu | 1 set | Bochu | |

6 | Y-axis drive system | High speed bus servo | 2 sets | Delta | |

7 | X-axis drive system | High speed bus servo | 1 set | Delta | |

8 | Z-axis drive system | High speed bus servo | 1 set | Delta | |

9 | Reducer | Motoreducer/Donlim | 3 set | France/Japan | |

10 | Electrical control element | Omron/Schneider | 1 set | Original and authentic | |

11 | Linear guide | Hiwin | 1 set | Taiwan | |

12 | Grinding rack | YYC; | 1 set | Taiwan | |

13 | Proportioning valve | Aventics | 1 set | Germany | |

14 | Industrial computer | Computer | 1 set | Standard model | |

15 | Nose | Aeronautical extruded cast aluminium | 1 set | Standard model | |

16 | Appearance sheet metal | Huaxia Star Industrial Design | 1 set | Well-known design team | |

More new models are available

Fiber Laser Cutting Machine Global OEM best-seller

|  |

Options for Laser Power

1000W-30000W

It can do the following

Because it is equipped with:

●The laser cutting head, controlled by capacitance induction, so that the distance between the nozzle and the workpiece surface is always consistent, and the planar and uneven curved surface cutting can be completed.

●Computer design and programming to complete a variety of complex processing, non-contact cutting more beautiful;

●Functions such as lightning perforation of 10,000-watt cutting thick plates, perforation and slag removal, and fine process of sub-layer greatly improve the efficiency and stability of high-power cutting;

●The graph track, directly drawn or editted in the system of this machine; Combined with mobile phone photo layout, machine tool visual positioning realizes tail material reuse; It can be connected to MES and other systems to collect equipment status and intelligently analyze early warning maintenance requirements;

●The bus system, matched with the bus servo drive, which detects the servo torque in real time, and automatically stops when it hits a heavy object to ensure the safety of machine tools and personnel;

Fire-proof brick design, imitating heat insulation, prolonging the service life of the machine tool;

●Double flue smoke exhaust, partition dust removal design, better effect of smoke exhaust and dust removal.

All these are attributable to Bochu

|  |  |

| 5 Laser (Maxphotonics) | Laser Head (RayTools) | Servo Drive (Delta) |

|  | |

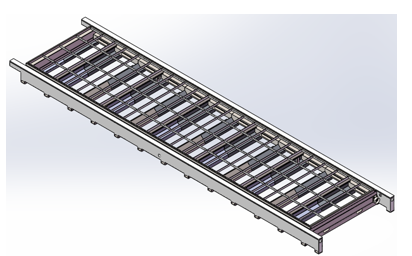

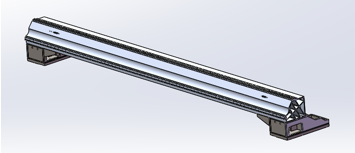

| Honeycomb carbon structure, plate welding heavy-duty high-strength bed | Crossbeam (high-strength aviation extruded aluminum alloy profiles) |

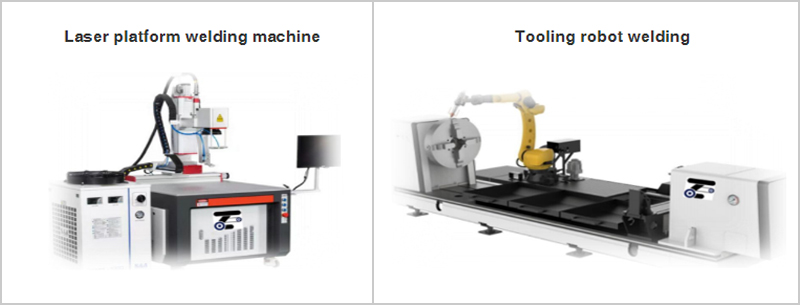

To make your workshop neat and safe, we launched the following:

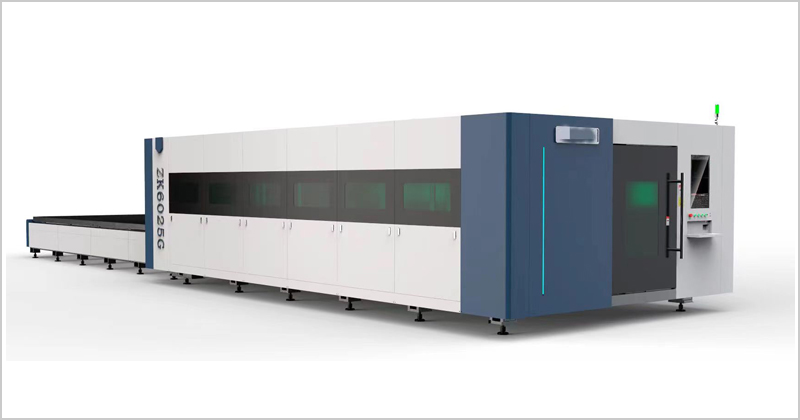

Medium and high power large encirclement laser cutting machine

● Repeated positioning precision ± 0. 03 mm

● Ultra-large breadth ten-thousand-watt processing aircraft carrier

● Faster processing efficiency & top cutting quality

● Performance upgrade, comprehensive optimization, super processing capacity, double efficiency

● Three-dimensional five-axis laser cutting head

● ± 45 ° Groove Cutting

● Processing width (L * W): (12m-45m) * (3m-5m)

Machine Working Parameters

Model | CCMT-3015 | Machining dimension | 3000 * 1500mm |

Positioning Position | ± 0. 03 mm | Repeated positioning accuracy | ± 0. 02 mm |

Area for Installation | 4900 * 2500 * 2300mm | Voltage, power (excluding peripherals) | AC380V, 15KW |

Area for Installation | Carbon steel, stainless steel, galvanized sheet, cold rolled sheet, electrolytic sheet, brass, copper, etc | ||

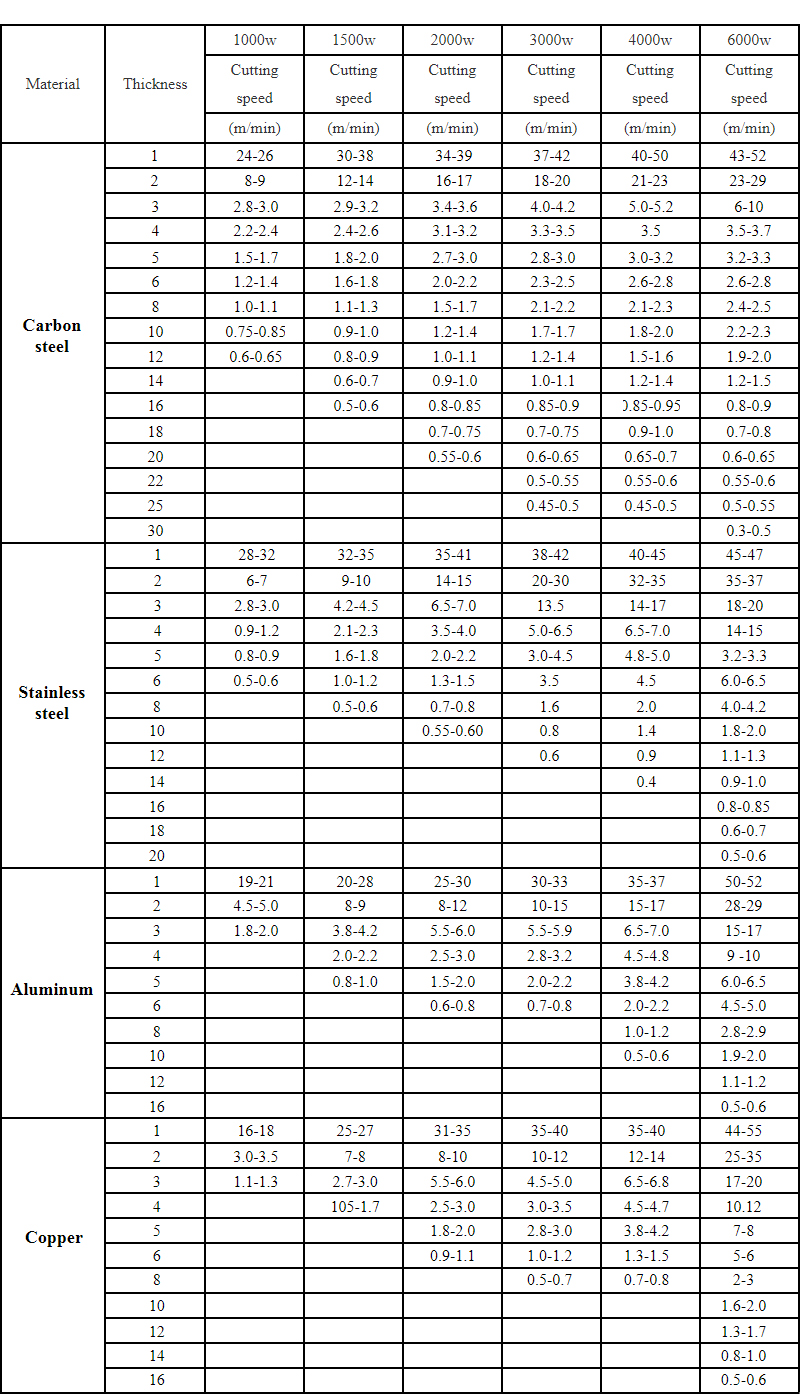

Laser Cutting Parameters