- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

Who Am I

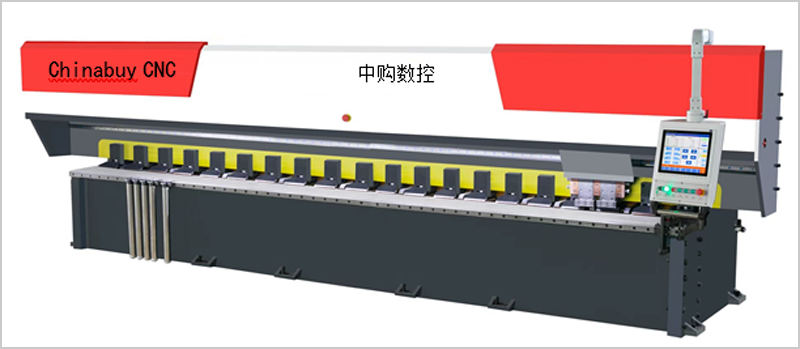

The full CNC sheet metal v grooving machine adopts advanced CNC system and is of novel design, with high processing accuracy, simple operation, free of noise and vibration. This machine is used to make grooves, U-grooves and other irregular grooves on sheet metal workpieces (including stainless steel sheet metals, aluminum veneers, aluminum-plastic plates, copper plates, iron plates and other special sheet metals.), especially suitable for processing V-groove before bending the sheet metal workpieces.

Confirgurations

No. | Name | Brands | |

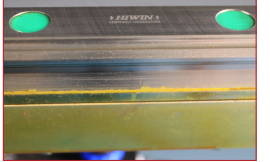

1 | High-precision ball screw | Taiwan HIWIN | |

2 | Precise linear guide | Taiwan HIWIN | |

3 | Angular contact ball bearing | Japan NSK | |

4 | White steel planing blade | Made in Sweden | |

5 | Servo motor | Taiwan HUST | |

6 | Electrical element | Schneider Electric | |

7 | Server driver | Taiwan HUST | |

8 | Power cable | Imported from Germany | |

9 | Operating system | Taiwan HUST | |

Our Strengths

● Vertical CNC sheet metal v grooving machine is researched and developed by our scientific researchers and engineers based on previous sheet metal v grooving machines at home and abroad. This machine has all the performance of traditional models and has fully solved a series of problems encountered by users in the on-site operation.

● The machine bed is welded with steel plates, and the internal stress is eliminated by vibratory stress relief, so that it is of superior strength, rigidity and stability compared with equivalent machines in the industry.

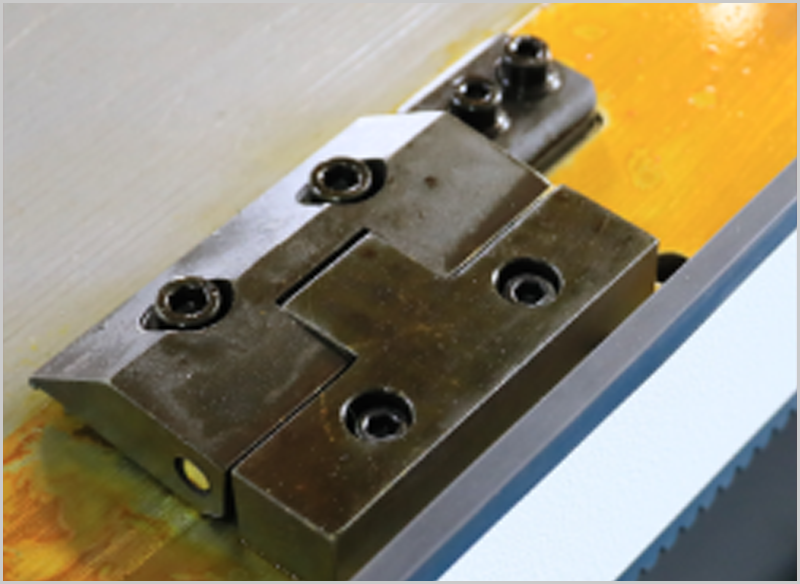

● The machine is designed ingeniously with the rear feeding structure and the universal ball, so that it will not damage the sheet metal surface when feeding and discharging. Adjustable movable workbench surface can ensure the precision of each part of the groove depth.

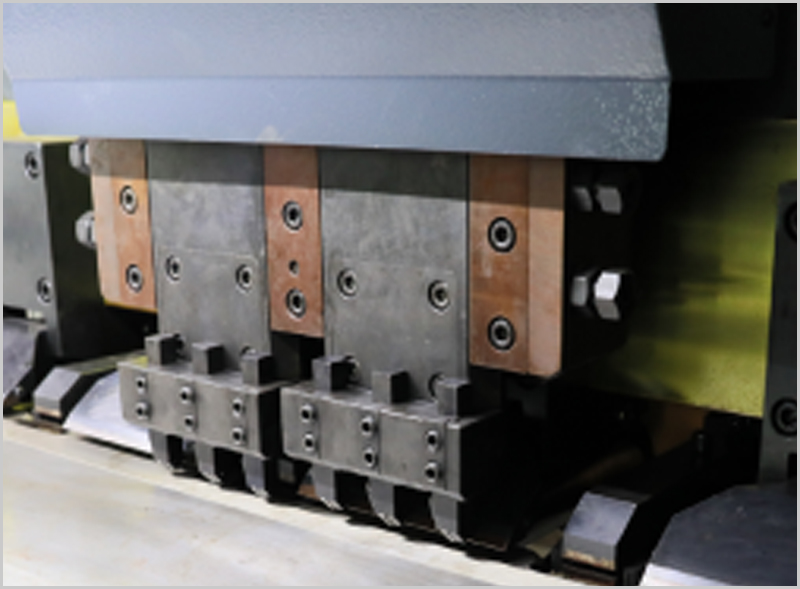

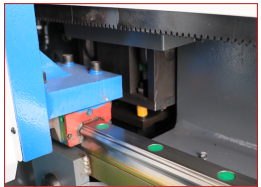

● In terms of fabrication technology, the front and rear of the machine is equipped with five white steel cutters respectively, which improves the processing efficiency. In addition, the shape of the cut-groove can be arbitrarily adjusted as required by the operators so that the workpieces are diversified.

● Designed with full hydraulic clamping and pressing, the machine can run fast and stably. The jaw is inlaid with hard alloy, which greatly prolongs its service life, prevents occurrence of scratches and inclusion of metal filing and other substances, and effectively protects the appearance quality of the workpiece. The spray cooling method is used in the machining process, which greatly improves the durability of the cutters and reduces the costs for using such machines.

● The machine is provided with high-speed alloy steel gear racks, large-pitch ball screws, and high-precision and silent linear guides. The spindle system is driven by a high-torque servo motor with an imported star reducer. Therefore, the cutter holder is stable and fast when machining the workpiece.

● The workbench is made from high-strength sheet material as the base surface, so that the workbench is not likely to be worn when machining the workpieces. Moreover, the workbench top and the workpiece on the machine body are adjustable, so that the precision of the distance between the cutter nose and each point on the workbench surface is guaranteed to be about 0.02 mm.

● The machine adopts PLC HMI programming and special system, which is convenient for operators to learn, understand, and make accurate positioning.

● With a cylindrical positioning structure, the machine has a positioning precision up to 0.02mm.

● The machine has a concise, elegant and beautiful shape, provided with frame structure, which conforms to the operating habits of various technicians so that the operators can fully meet the requirements for production and technique of workpieces.

Parameters

SN | Contents | Demand parameters | |

1 | Model | B6 Vertical 1600×4200 | |

2 | Thickness of processed plates | 0.4-6mm | |

3 | Length and width of processed plates | 1600x4200mm | |

4 | Cutting speed is variable speed feasible | 5M-70M/min | |

5 | Feeding speed | 0.5-20M/min | |

6 | X-axis minimum unit set | 0.01mm | |

7 | X-axis positioning precision | ±0.02mm | |

8 | Y-axis minimum unit set | 0.01mm | |

9 | Y-axis positioning precision | ±0.02mm | |

10 | Z-axis minimum unit set | 0.01mm | |

11 | Z-axis positioning precision | ±0.02mm | |

12 | X-axis motor power | 1.5KW | |

13 | Y-axis motor power | 3KW | |

14 | Z-axis motor power | 0.4KW | |

15 | Flatness of work surface | ±0.01mm | |

16 | Feeding mode | Rear feeding | |

17 | Can the workbench be easily replaced ? | Yes | |

18 | Is the workbench hardened? | Yes | |

19 | Number of installed cutters | Five white steel cutters | |

20 | Maximum one-time planing depth | 1.2mm | |

21 | Maximum grooving depth | 2.5mm | |