- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

The machine is a specialized high-speed full servo-driven CNC sheet metal v groover. In the conventional bending processes, a significant arc is typically formed at the bending point, which becomes more prominent if the sheet is thicker. The presence of such large arc angles detracts from the overall aesthetics of the product. To address this challenge, we have introduced a series of CNC sheet metal V-grooving machines featuring a novel design concept. This series boasts high processing precision, ease of operation, and reliable performance. It is utilized for V-groove processing on stainless steel, ordinary iron sheet, aluminum veneer, alloy sheet metal, copper, and other sheet metals, particularly suitable for V-groove processing prior to sheet metal bending.

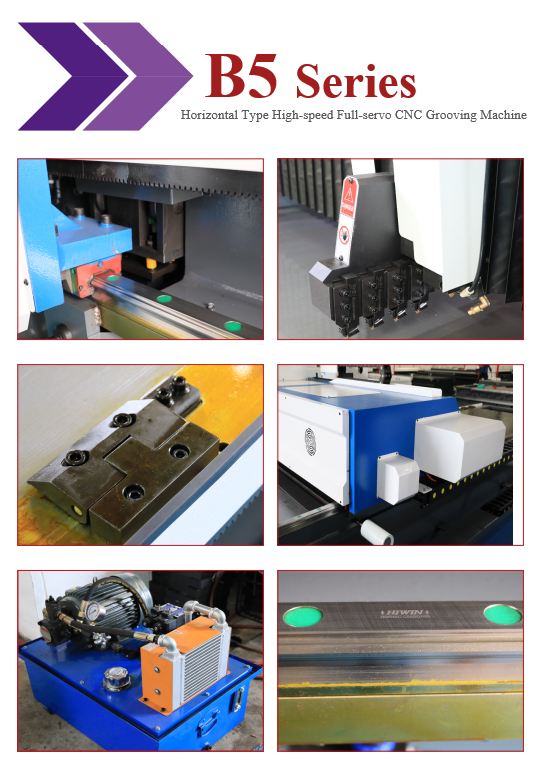

Configuration

No. | Name | Brands | |

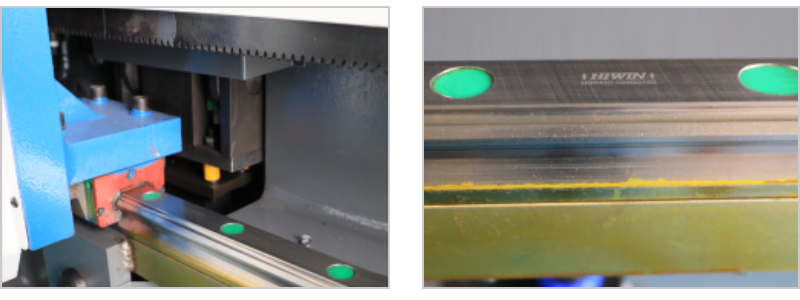

1 | High-precision ball screw | Taiwan HIWIN | |

2 | Precise linear guide | Taiwan HIWIN | |

3 | Angular contact ball bearing | Japan NSK | |

4 | Servomotor | Taiwan HUST | |

5 | Power cable | Germany IGUS | |

6 | Pneumatic element | Taiwan AIRTAC | |

7 | Alloy rack | Rack and gear from Taiwan YYC | |

8 | Operating system | Taiwan HUST | |

What Makes It So Special?

● Lately developed by us, following improvements made during R&D on several generations of v grooving machines.

● Strong expertise in this field.

● Software independently developed by our technical team.

● Designed with 4-axis full servo control, representing a significant breakthrough compared to all gantry-style grooving machines at home and abroad.

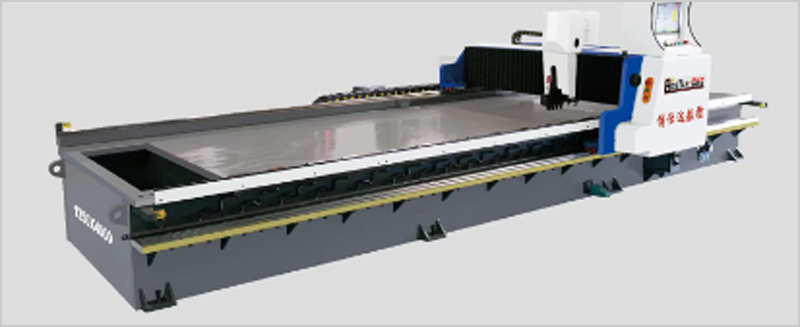

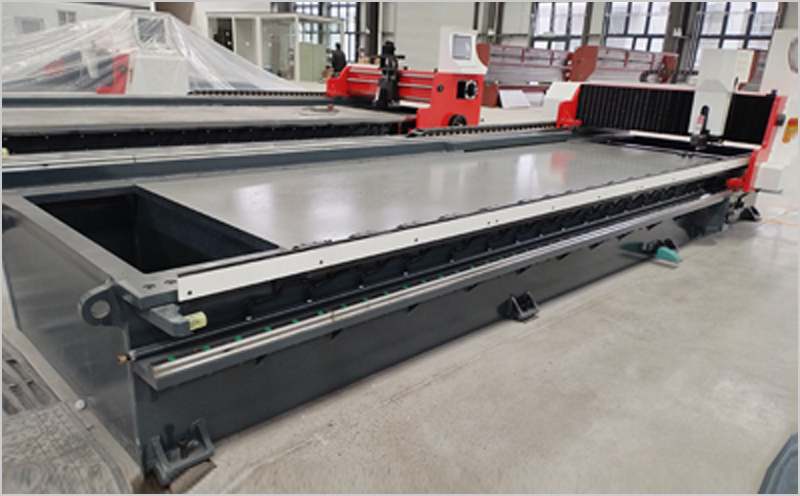

● Workbench-style structure made from high-strength steel plates welded together.

● Workbench-style structure made from high-strength steel plates welded together.

● With heat treatment, heat preservation, and tempering processes, welding stresses are eliminated, ensure high strength and excellent stability.

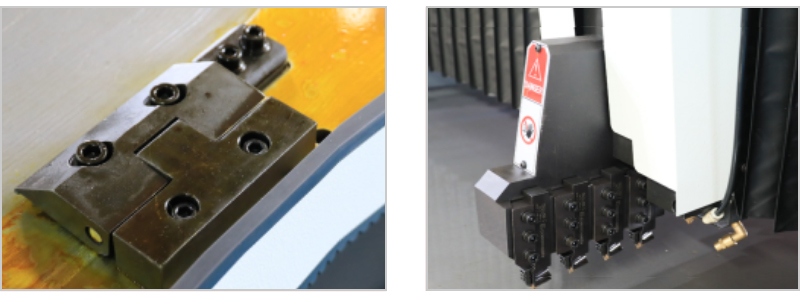

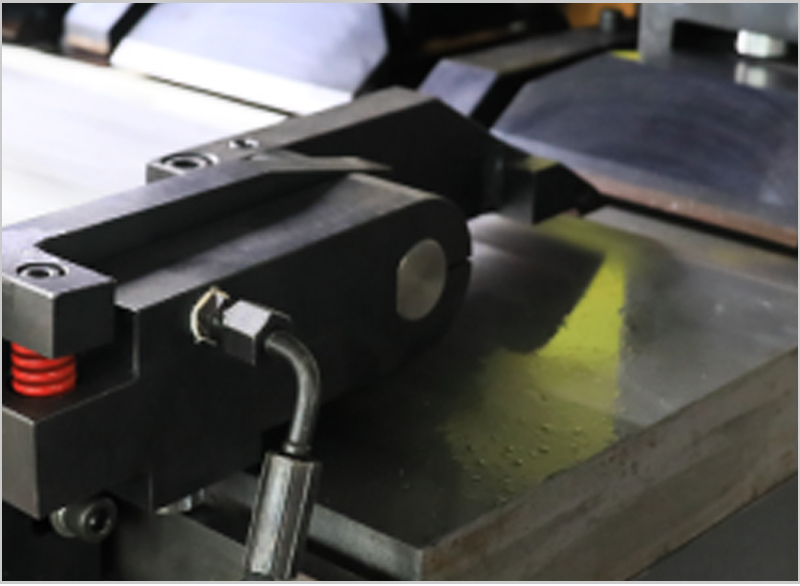

● Four forming blades backwards and forwards, significantly reducing the generated iron filings in processing.

● Full hydraulic clamping and pressing, ensuring rapid operation and producing no clamping or indentation marks on the processed workpieces.

● Monitored with cooling and blowing, and an alarm device incorporated for additional safety.

● Full hydraulic control for clamping and pressing to ensure conservation and environmental protection.

● High-speed alloy steel pinion and rack, along with large-pitch ball screws and high-precision and silent linear guide rails.

● The spindle system driven by a high-torque servo motor to ensure stability and efficiency while machining workpieces.

● Gantry frame incorporates 4 ultra-silent slides, setting it apart from any comparable products.

● CNC system makes it easy for operators to learn and understand the key points while ensuring precise positioning.

Overall concise, elegant, and visually appealing design, with frame structures on the wall panels that cater to the operational habits of various technicians.

What It Can Do

No. | Item | Standard Parameters |

1 | Model | 1250x4000 |

2 | Machined sheet metal thickness | 0.4-8mm |

3 | Length and width of machined sheet metal | 1250x4000 |

4 | Cutting speed/Variable speed capability | 5M-120M/min |

5 | Workbench adjustment | Self-grooving and workbench compensation functions |

6 | Min X-axis set | 0.01mm |

7 | X-axis positioning precision | ±0.001mm |

8 | Min Y-axis set | 0.01mm |

9 | Y-axis positioning precision | ±0.001mm |

10 | Min Z-axis set | 0.01mm |

11 | Z-axis positioning precision | ±0.001mm |

12 | X1-X2 axis motor power | 1KW-1KW |

13 | Y-axis motor power | 5.5KW |

14 | Z-axis motor power | 1KW |

15 | Workbench flatness | ±0.03mm |

16 | Feeding mode | The sheet remains stationary while the tool holder moves. |

17 | Can the workbench be replaced | Not replaceable |

18 | Is the workbench annealed to eliminate stress | Yes |

19 | Number of installed cutters | 4 alloy cutters |

20 | Max single cut depth | 0.8mm |

21 | Max grooving depth | 2.5mm |

22 | Dimension | 6300*2300*1680 |

23 | Weight | 8000KG |

24 | CNC system | Taiwan HUST |

25 | Servomotor | Taiwan HUST |

26 | Servo drive | Taiwan HUST |

27 | Travel switch | Brand from Japan/Germany |

28 | Pneumatic element | Brand from Taiwan |

29 | Hydraulic station | MENGXUAN (Hydraulic) |

30 | Guide rail | Taiwan HIWIN |

31 | Ball screw | Taiwan HIWIN |

32 | Cooling | Available |

33 | Cable | Brand from Germany |

34 | After-sales service | 1-year warranty |

This video show how the machine works efficiently to manufacture better workpieces.