- Scan Our WeChat QR Code to Add Me to Your Contacts for Chat

What Makes Me Special

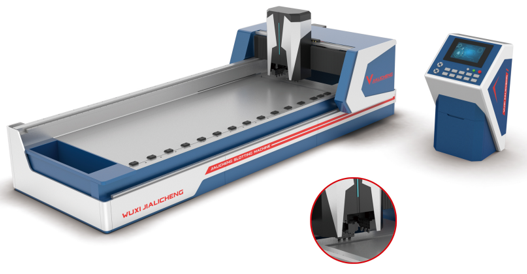

The machine is a specialized high-speed full servo-driven CNC sheet metal v groover. In the conventional bending processes, a significant arc is typically formed at the bending point, which becomes more prominent if the sheet is thicker. The presence of such large arc angles detracts from the overall aesthetics of the product. To address this challenge, we have introduced a series of CNC sheet metal V-grooving machines featuring a novel design concept. This series boasts high processing precision, ease of operation, and reliable performance. It is utilized for V-groove processing on stainless steel, ordinary iron sheet, aluminum veneer, alloy sheet metal, copper, and other sheet metals, particularly suitable for V-groove processing prior to sheet metal bending.

Configurations

No. | Name | Brand | |

1 | Numerical control system | Mitsubishi, Japan | |

2 | Servo motor | Taiwan Saidefu | |

3 | LV electrical components | Schneider, France | |

4 | X-axis linear guide rail | 45 rollers, Shandong Catte | |

5 | Ball screw | Taiwan Hiwin | |

6 | Main cable | Igus, Germany | |

7 | Alloy cutter | Korloy, Korea | |

8 | Gear and rack | Taiwan YYC | |

Our Strengths

●The four-side V grooving machine is developed from an updated version of the traditional gantry V groover. In addition to retaining all the advantages of a standard gantry V grooving machine, it offers the capability to groove longitudinally and transversely on all sides, ensuring fast cutting speed, high precision, and leaves no indentation on the sheet metal surface.

●If being worn in use, the tabletop can self-repair, thus effectively extending its lifespan.

● With the edge pressing for precise positioning, the machine ensures that there is no contact between the presser foot and the sheet metal surface in operation, ensuring a defect-free surface without any indentation thus guaranteeing workpiece quality.

Parameters

1 | Max length of grooved sheet metal | 4000mm | |

2 | Max width of grooved sheet metal | 1500mm | |

3 | Max thickness of grooved sheet metal | 3.0mm | |

4 | Min thickness of grooved sheet metal | 0.6mm | |

5 | Max cutting depth | 2.0mm | |

6 | Max cutting depth of the initial cut | ≤0.8mm | |

7 | Min margin | ≤8mm | |

8 | Max X-axis left-right movement distance | 4300mm | |

9 | Max X-axis movement speed | 100m/min | |

10 | X-axis (vertical) control and precision | + 0.1mm | |

11 | X-axis motor power | 5.5KW | |

12 | Max Y-axis forward-backward movement distance | 1500mm | |

13 | Y-axis forward-backward movement resolution | 0.01mm | |

14 | Y-axis motor power | 3KW | |

15 | Y-axis (horizontal) control and precision | +0.05mm | |

16 | Max Y-axis speed | 80m/min | |

17 | Max Z-axis vertical movement distance | 100mm | |

18 | Z-axis vertical movement resolution/span> | 0.01mm | |

19 | Z-axis motor power | 1KW | |

20 | Z Axis (cut depth) control and precision | +0.02mm | |

21 | Z-axis rotation angle | 90° | |

22 | Z-axis motor power | 1KW | |